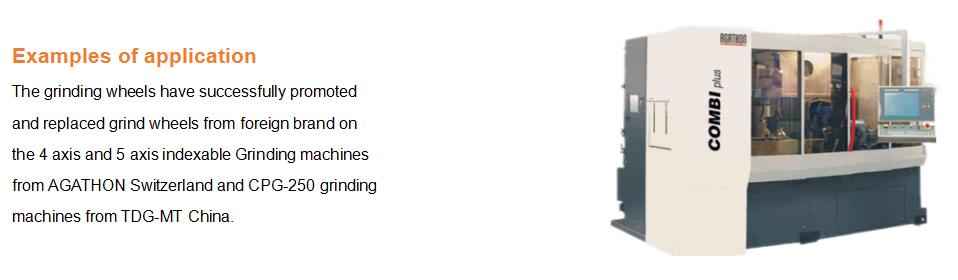

A Diamond Grinding Wheel Is A Cutting Tool Having Thousands Of Sharp Abrasive Grains On The Face Of It, Which Do The Cutting Action. We Offer Grinding Wheels Which Are Highly Acknowledged For Their Various Attributes Due To Which These Are Highly Demanded Among The Vast Client Base. Our Products Are Available At The Most Affordable Prices And Can Also Be Customized As Per The Specific Demands Of Clients.

1. Compared with ordinary corundum and silicon carbide grinding wheel, it has strong grinding force, low temperature and less wear of grinding wheel.

2. Can be adapted to the effects of various coolants;

3. The shape of grinding wheel is good and the precision of grinding workpiece is high.

4. There are more pores in the grinding wheel, which is beneficial to chip removal and heat dissipation, which is not easy to block and burn the workpiece.

5. The self-sharpening of grinding wheel is better, the time of dressing interval is long, and the dressing is easier.

1. Higher efficiency

2. Higher edge quality

3. Better consistency of inserts

4. Longer life

5. Advanced technology

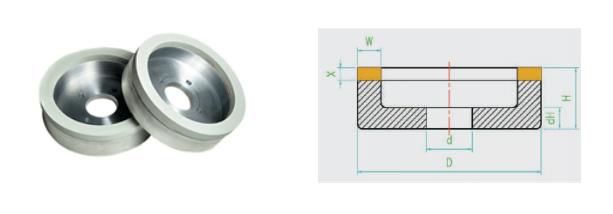

| Diameter

(D) |

Hole diameter(d) | Heigh

(H) |

Basal height

(dH) |

Disc width

(W) |

Grinding thickness(X) | Grain size | Concentration |

| 50 | 13 | 25 | 6 | 5,6 | 5,8 | Upon request | Upon request |

| 75 | 20 | 30 | 10 | 5,6 | 5,8 | ||

| 150 | 32,40 | 35,40 | 15 | 5,10,15 | 5,8,10 | ||

| 250 | 215 | 50 | / | 8,10,15 | 5,8,10 | ||

| Design and manufacture kinds of non-standard abrasive according the requirements. | |||||||

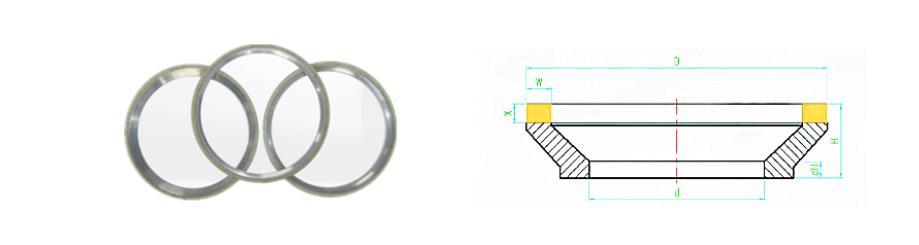

| Diameter

(D) |

Hole diameter(d) | Heigh

(H) |

Basal height

(dH) |

Disc width

(W) |

Grinding thickness(X) | Grain size | Concentration |

| 400 | 340 | 30 | 5 | 5,10,14 | 5,8 | Upon request | Upon request |

| 400 | 353 | 25 | 8 | 5,10,14 | 5,8 | ||

| 400 | 368 | 30 | 6 | 5,10,14 | 5,8 | ||

| 350 | 240 | 75 | 15 | 8,10 | 5,8 | ||

| 350 | 300 | 30 | 10 | 10 | 6 | ||

| Design and manufacture kinds of non-standard abrasive according the requirements. | |||||||